By SUN Junqi's Group

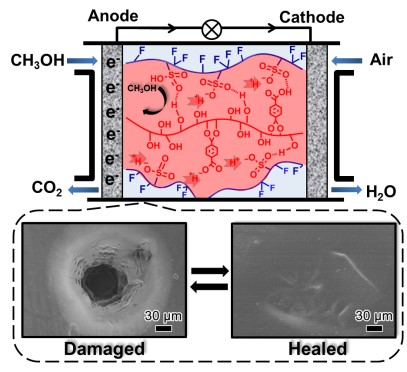

As one of the most promising power conversion technologies, direct methanol fuel cells (DMFCs) are capable of delivering a much longer operating time than lithium ion batteries for portable electronic devices due to the high specific energy density of methanol (6100 W h/kg). In DMFCs, the proton exchange membrane (PEM) plays a critical role in the overall performance of the cells. PEMs are prone to be swollen in aqueous methanol solution, generating mechanical defects such as micro-cracks and pinholes under sustained osmotic pressure. Meanwhile, the unavoidable shock and impact on DMFCs can damage PEMs, especially when the DMFCs are used under harsh conditions. These mechanical damages on PEMs can lead to massive methanol permeation from the anode to the cathode, dramatically reducing their service life and resulting in the failure of cells.

To solve this problem, we present the first fabrication of intrinsically healable PEMs that exhibit satisfactory mechanical stability, enhanced proton conductivity, and suppressed methanol permeability via hydrogen-bonding complexation between Nafion and PVA followed by post-modification with 4-carboxybenzaldehyde (CBA) molecules. The CBA/Nafion−PVA membrane shows a proton conductivity of 0.11 S/cm at 80 °C, which is 1.2-fold higher than that of a Nafion membrane. The incorporated PVA also gives the CBA/Nafion−PVA membranes excellent proton conductivity and methanol resistance. Most importantly, the CBA/Nafion−PVA membranes can heal mechanical damage and restore their original proton conductivity and methanol resistance under DMFC working conditions. Therefore, the service life and reliability of the DMFCs can be largely enhanced. The work was published in Advanced Materials (Adv. Mater. 2018. 1707146).